New Perspectives on Automotive Recycling

The automotive industry is undergoing significant transformations, driven by advancements in technology and a growing emphasis on environmental responsibility. As vehicles become more complex, incorporating diverse materials and sophisticated electronic systems, the methods and priorities for automotive recycling must also evolve. This article explores the changing landscape of vehicle decommissioning and material recovery, highlighting the crucial role of innovative approaches in achieving a circular economy for the automotive sector.

The automotive sector faces a dual challenge: meeting demand for new vehicles while managing the end-of-life process for older models responsibly. Traditional recycling methods, while effective for conventional steel and aluminum, are being re-evaluated to address the unique characteristics of modern vehicles, particularly those with advanced powertrains and complex electronic components. A shift towards more comprehensive and sustainable recycling practices is essential for reducing waste and conserving valuable resources globally.

The Role of Sustainability in Automotive Recycling

Sustainability is at the forefront of modern automotive design and end-of-life management. As global environmental concerns grow, the focus is increasingly on minimizing the ecological footprint of vehicles throughout their entire lifecycle. This includes the responsible sourcing of materials, energy-efficient manufacturing processes, and robust recycling programs. Effective automotive recycling contributes significantly to sustainability by reducing the need for virgin raw materials, lowering energy consumption associated with primary material production, and diverting waste from landfills. The goal is to maximize material recovery and reintroduction into the manufacturing cycle, fostering a more circular economy for transport and mobility.

Innovations in Materials and Engineering for Recycling

Modern vehicles incorporate a wide array of advanced materials, including high-strength steels, aluminum alloys, carbon fiber composites, and various plastics, chosen for their performance, efficiency, and safety attributes. While these materials offer significant benefits during a vehicle’s operational life, they present new challenges for recycling. Innovations in materials science and engineering are crucial for developing methods to efficiently separate, recover, and reuse these complex material streams. Research is ongoing into advanced shredding technologies, material sorting techniques like sensor-based separation, and chemical recycling processes for plastics, all aimed at improving the purity and value of recovered materials for re-entry into the manufacturing supply chain. This innovation is vital for future automotive design.

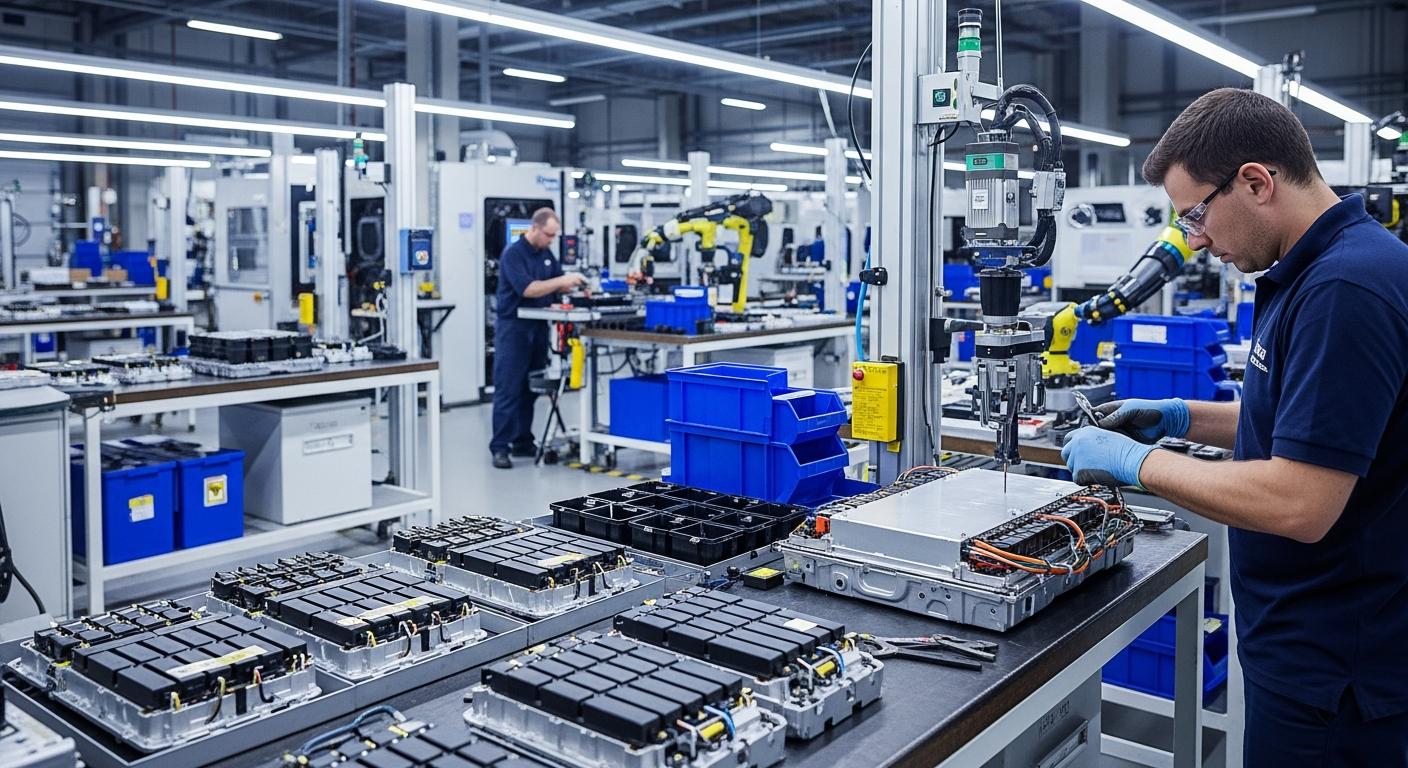

Recycling Electric Vehicle Batteries and Powertrains

The rise of electric vehicles (EVs) introduces new considerations for automotive recycling, primarily concerning high-voltage batteries and electric powertrains. Lithium-ion batteries, central to EV functionality, contain valuable materials such as lithium, cobalt, nickel, and manganese, along with critical rare earth elements in electric motors. Developing efficient and safe processes for disassembling, discharging, and recycling these components is paramount. Current efforts focus on two main approaches: direct recycling, which recovers cathode and anode materials with minimal processing, and hydrometallurgical or pyrometallurgical processes, which extract individual metals. Establishing a robust charging infrastructure and clear guidelines for battery collection, transport, and processing is a key area of development to support the widespread adoption of electric mobility and ensure resource security.

Design and Manufacturing for Enhanced Recyclability

Integrating recyclability into the initial design and manufacturing phases of a vehicle offers significant advantages. This approach, often termed ‘design for disassembly’ or ‘circular design,’ focuses on making vehicles easier to take apart and their components simpler to recycle or reuse at the end of their life. This involves selecting materials that are easily separable, minimizing the use of mixed materials that are difficult to process, and clearly labeling components. For instance, modular design for components like sensors and software systems can facilitate their removal and potential reuse or upgrade. Such foresight in engineering and design can significantly improve the efficiency and economic viability of automotive recycling, contributing to overall sustainability goals. It also impacts the overall performance and efficiency of the recycling process itself.

The Future of Automotive Recycling: Autonomous and Smart Systems

The advent of autonomous vehicles, with their sophisticated sensors and complex software systems, will further reshape automotive recycling. These vehicles contain advanced electronics, lidar, radar, and camera systems, which require specialized handling at end-of-life. The recycling industry will need to adapt to safely recover and process these high-value components. Furthermore, the data stored within these smart systems, while protected by privacy regulations, may also need secure erasure. The continuous evolution of vehicle technology, including advancements in aerodynamics and lightweight materials, demands ongoing research and development in recycling techniques. The goal is to create a seamless transition from vehicle operation to responsible end-of-life management, ensuring that future transport and mobility solutions are truly sustainable.

Automotive recycling is undergoing a profound transformation, moving beyond basic scrap metal recovery to embrace complex material streams and advanced technological components. The shift towards electric and autonomous vehicles, coupled with a global drive for sustainability, necessitates innovative approaches in materials engineering, design for recyclability, and specialized processing for batteries and electronic systems. By continuously adapting and investing in new methods, the industry can ensure that vehicles, regardless of their powertrain or level of autonomy, contribute to a more circular and environmentally responsible future.